SuperPro Designer 101: Process Simulation for Bioprocessing

About Course

- Welcome to “SuperPro Designer® Basics: A Comprehensive Tutorial Course,” designed to provide an in-depth understanding of the essential steps and features required for modelling various processes using SuperPro Designer®. This course is tailored for students in chemical, bioprocess, biochemical, food, environmental, and allied engineering domains, ensuring they gain the practical knowledge and skills necessary to excel in their field.

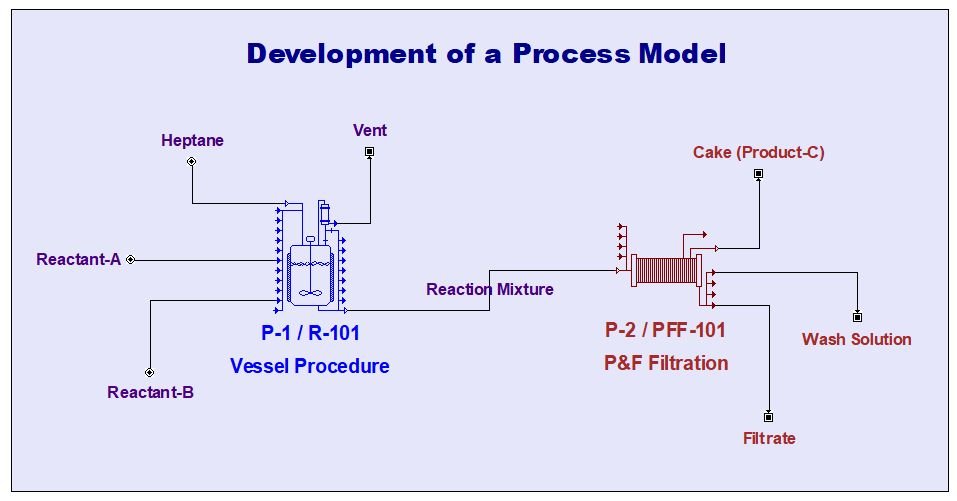

- This tutorial introduces the key initialization and evaluation steps essential for modelling a process with SuperPro Designer®. This foundational example will guide you through the fundamental steps and focus points required to capture and model any process, regardless of its type. The example chosen is a batch process, making it an excellent medium for discussing several scheduling issues. By following this example, you will acquire the basics needed to model any process, including your own projects.

- In this tutorial, you will work with model files installed under the “Examples” folder, specifically in the “Misc” subfolder shipped along with the SuperPro Designer Software. These files are designed to demonstrate a simple batch process, including a reaction step in a reactor and a filtration step. One model file focuses on designing the process and solving mass and energy balances with equipment in Design Mode to find appropriate sizes. This includes setting process scheduling information and analyzing scheduling, equipment utilization, and resource tracking results. Another model file evolves from the first by solving mass and energy balances for set equipment sizes in Rating Mode. It emphasizes evaluating throughput, debottlenecking analysis, and conducting a thorough economic assessment to determine the process’s viability.

- By the end of this course, you will be proficient in using SuperPro Designer® to model various processes, enhancing your engineering skills and preparing you for real-world applications.

Course Content

Introduction to Process Modeling and Simulation

-

• Role of Process Simulation and Scheduling Tools in Analysis and Optimization of Processes

Student Ratings & Reviews

No Review Yet